What are Gold Alloys?

An alloy is a material made by combining two or more metallic elements. Gold is considered a precious metal, but on its own it is generally too soft for most practical applications. Forming gold into alloys allows the properties of the gold to be combined with other metals for improved durability, workability, and colour.

Common Gold Carat Alloys

The most common gold alloys are made by mixing gold with silver, copper, zinc, nickel, iron, and cadmium. These metals are added to increase the strength and hardness of pure 24 carat gold.

Some of the most popular gold alloys include 18 carat gold, 14 carat gold, and 9 carat gold. The number marks the proportion of gold to other metals by weight. For example, 18 carat gold contains 18 parts gold and 6 parts alloyed metals.

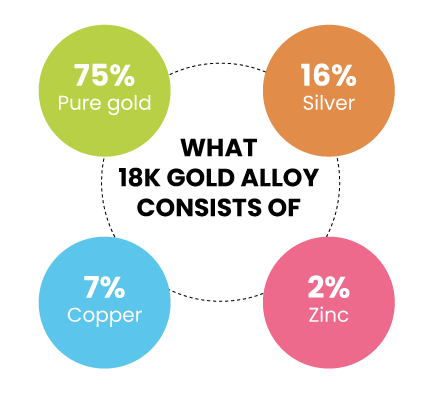

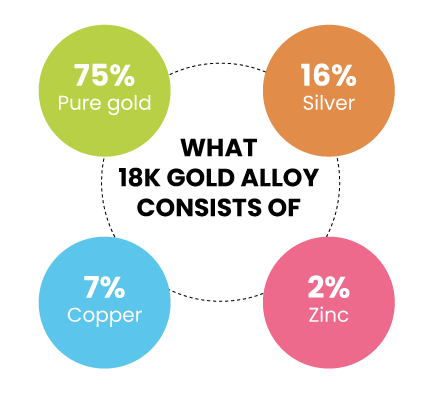

A common gold alloy is 18 carat yellow gold. It typically consists of 75% pure gold, 16% silver, 7% copper, and 2% zinc. The silver and copper help harden the gold, while the zinc prevents oxidation that can cause tarnishing. This combination of metals produces a bright golden yellow colour that is highly resistant to corrosion and scratching.

Some of the most popular gold alloys include 18 carat gold, 14 carat gold, and 9 carat gold.

14 carat yellow gold typically contains 58% gold and has a gold content between 18 carat and 9 carat gold. It is slightly harder than 18 carat and has a lighter yellow tone. The lower gold content makes it more affordable. 14 carat gold is commonly used for jewellery, watches, and decorative purposes.

White gold alloys substitute nickel, manganese or palladium for the copper and silver used in yellow gold. These alloys inhibit yellow colour, producing a pale silvery-white gold popular for jewellery. The metal rhodium is also applied as plating to harden white gold and enhance whiteness.

Coloured Gold Alloys

Red or Rose gold uses a high copper content to produce rose-tones ranging from pink to red. Green gold incorporates silver, iron, or cadmium to generate a pale green shade. Blue gold adds iron or ruthenium to create a bluish hue. These coloured gold alloys are specially formulated for decorative artistic applications.

In addition to colouring, gold alloys like 18 carat and 14 carat gold increase the hardness of pure gold for practical use in jewellery, coins, medals, and electronics. Alloying expands the versatility of gold while retaining its natural beauty and lustre.

Varying the metals and proportions used in the alloy allows for tailored properties like durability, colour, melting point, and electrical conductivity. Gold’s malleability also makes it suitable for precision casting and creating detailed features when alloyed. With innovations in alloy technology, gold continues to find new applications across many industries.